Wire bonding, the electronic interface from micro to macro

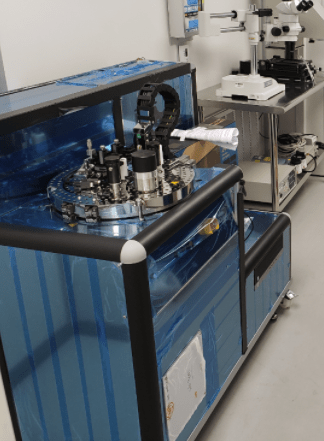

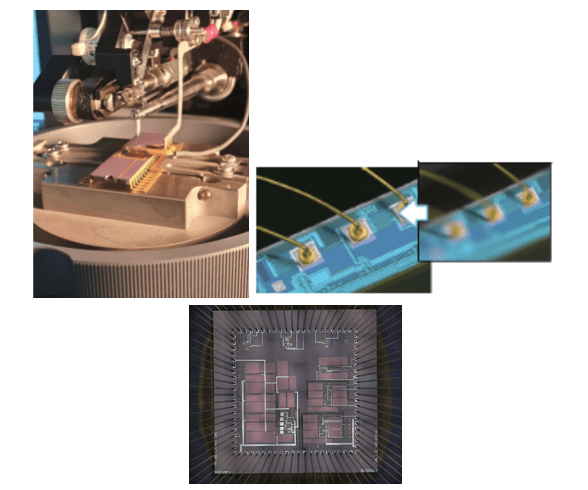

In the clean room of CIDESI Querétaro, we have a wire bonder equipment “iBond5000 Dual bond model” from the company Kulicke & Soffa where we carry out the spinning processes of the semiconductor based devices with their packaging. We use this process primarily to verify the functionality of our N-MOS devices.

The wire bonding technique is the most used to make interconnections between integrated circuits (IC), semiconductor based devices and their packaging during the manufacture of microelectronic devices. With this technique it is also possible to interconnect printed circuit boards (PCB). The wire bonding technique is considered the most effective technology for its flexibility and cost-benefit to assemble a vast majority of semiconductor base devices. Besides that it can be used with frequencies above 100 GHz.

For the wire bonding process, there are three physical principles of operation: thermosonic, thermocompression, and ultrasonic. The equipment that we have in the clean room of CIDESI Querétaro, performs the thermosonic and ultrasonic bonding or spinning processes, using the ball bonding and wedge bonding technique, we obtain this with a simple adaptation that the team has. Below we will tell you more about the principles of operation of these processes.

Thermosonic spinning

This technique is implemented using heat, force and ultrasonic energy to bond a gold wire to a substrate with a gold or aluminum surface. In this technique, heat is applied by placing the substrate in a hot holder. Some systems used to heat the tip, which improves joint performance, then a force is applied by applying pressure to the cable when it is in contact with the joint surface. Ultrasonic energy is delivered by vibrating the tip when the wire is in contact with the surface. Then, ultrasonic spinning is performed under ambient temperature conditions and is implemented with a combination of ultrasonic force and energy. The pressure used and the bonding time in the ultrasonic and thermosonic bonding techniques are much lower and shorter than those required with thermocompression spinning. Although gold wires can be used to join gold surfaces in ultrasonic bonding, it is used primarily to join aluminum wires on gold or aluminum substrates, being the dominant technique in power electronics when implementing long aluminum wires.

Thermocompression spinning

Is implemented using a combination of heat and force to deform the wire and make the joints or connections. The important parameters with this technology are time, temperature and bond strength. In this technique, a high temperature (above 300 °C) and a long waiting time are required to make the joints. We have to consider that these high temperatures can damage sensitive integrated circuits and that the process is sensitive to contaminants on the junction surface.

As we mentioned earlier, there are two wire bonding modalities that can be used in this process. For ball bonding, it is restricted to using gold and copper wires, usually the amount of heat is limited to using wires with small diameters, approximately 10 micrometers. For wedge bonding, larger diameter wires are used in high power electronics applications. With these techniques, ball and wedge bonding, the wires are glued from the two ends using a combination of pressure, ultrasonic energy and, when heat is required, it is used to make the connection (heat is used to make the metal softer). The correct combination of temperature and ultrasonic energy is used to maximize the reliability and mechanical strength of the connection. When we use the wedge bonding technique, the wire is stretched according to the first gluing, this increases the waiting time of the process due to the alignment of the equipment. In ball bonding, no alignment is needed, since the initial bond has no direction of preference, so the wires can be stretched in any direction. Finally, the Admon of the Division of Microtechnologies at CIDESI Querétaro is interested that the infrastructure will be useful for the development of both scientific and industrial projects.

Wafer Bonding

Our equipment has the vitality of perform Anodic, Eutectic, Direct (High & Low Temperature) Glass frit, Adhesive, Solder & Thermo-compression wafer bonding.

Wafer bonding has found many applications in the field of MST, MEMS, III-Vs & ICs and AML machines can be used in the following applications:

- High accuracy aligned adhesive bonding “best tool”.

- New UHV bonding environment for Quantum devices

- MEMS devices – pressure sensors, accelerometers.

- Vacuum encapsulation – ‘best tool on the market’.

- 1st Level Packaging of devices e.g. silicon microstructures to isolate package induced stresses.

- Wafer Scale Packaging – MEMS & IC.

- III-V bonding e.g. new high performance LEDs.

- 3D Interconnects & TSV.

- Advanced bonded substrates e.g. silicon-on-glass (SOG).

- Smart cut – Layer transfer.

- Microfluidics.