During the manufacturing processes of devices such as sensors and integrated circuits, materials such as semiconductors, dielectrics and metals are exposed to different processes and pollutants, in which the physical integrity of these materials can be altered and therefore, which will be not convenient during the fabrication processes. In the clean room at Cidesi, we have a Chemical Vapor Deposition (CVD) equipment for Parylene-C depositions that helps us to avoid and protect our materials during the fabrication process.

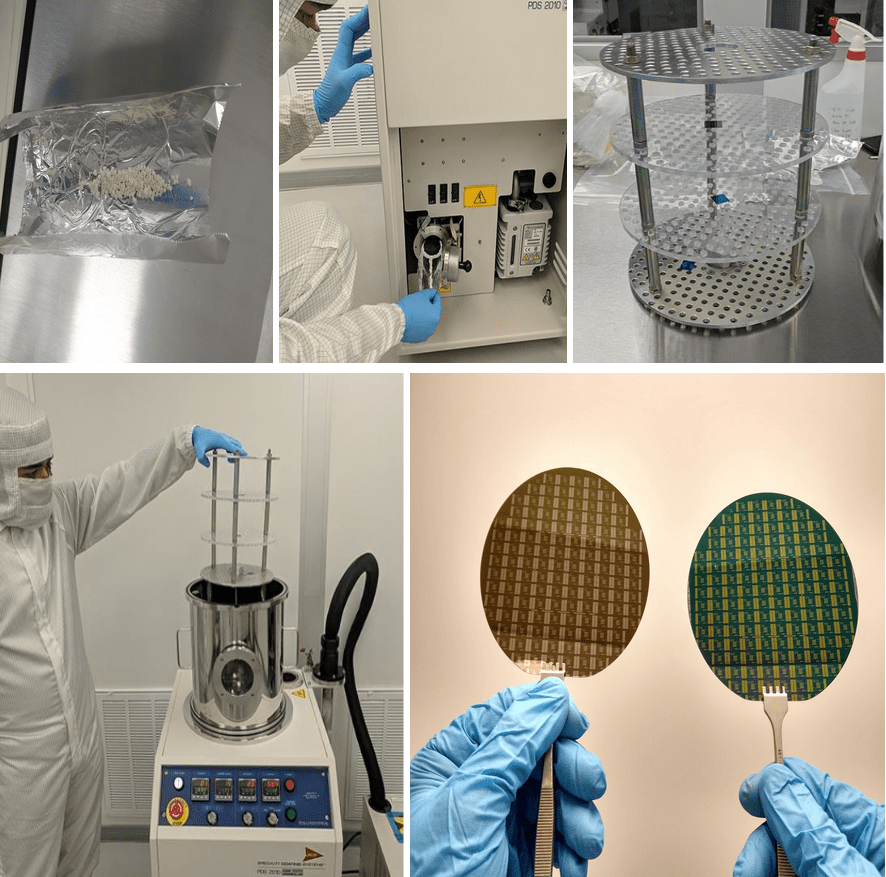

The Parylene-C deposition system is located in the clean room at CIDESI Querétaro. This system is used in research and technological projects such as sensors and integrated circuits.

Parylene-C applications

Conformal coatings are used in a wide spectrum of the industries, including electronics, medical devices, automotive, military, and aerospace. They are used for protection, biostability and surface modification to improve the overall reliability of the final product or application. In the cleanroom of the Microtechnologies division at Cidesi Queretaro, most of the time we use Parylene-C coatings as a protective film for semiconductors, dielectrics and metals, which could be affected during the acid or plasma attack processes that are widely used as was mentioned above.

The image shows David Velarde, a student of the Autonomous University of Querétaro in the Nanotechnology career during his professional practices. Currently David has joined as a project engineer in the Microtechnologies Division.

Parylene-C advantages

Parylene-C has superior dielectric strength (5000 volts/mil to 1 mil), a very low dissipation factor, excellent mechanical strength, very high surface and volume resistivities, and other superior electrical properties that remain virtually constant with changes in temperature.

In today’s commercial applications, Parylene-C is deposited in many thickness ranges, from a few nanometers to approximately 75 microns, depending on the demanded application of the Parylene-C film.

Parylene-C does not require a catalyst or solvents, eliminating environmental concerns. Due to the very low coefficients of static and dynamic friction, which are practically the same, Parylene-C can work as a dry film lubricant that helps a lot in devices such as miniature servo motors, where starting can be a problem.

Parylene-C works for multiple purposes including electrical insulation, moisture and chemical insulation, mechanical protection, to improve lubricity, and surface consolidation to prevent flaking or dust.

One of the characteristics of the Parylene-C coatings is that extremely thin layers can be deposited and excellent dielectric voltages are obtained. In addition, the water vapor transmission rate (WVTR) is compared to other used conformal lining materials. In this case, the WVTR for Parylene-C is higher than common polymeric materials, thus reducing surface corrosion and salinization.