“Micro-Electro-Mechanical Systems (MEMS)” fabrication usually uses complex methods in most cases, where it is necessary to implement specialized tools that can solve the needs of micro-machining. Among these processes are generally, photolithography, deposition of thin films by thermal evaporation and sputtering, oxidation of silicon wafers, bonding of substrates of different materials and deep attacks using reactive ions “Deep Reactive-Ion Etching (DRIE) ”. In this note we will focus on the DRIE system which is available in the clean room facilities of the Microtechnologies Division at CIDESI.

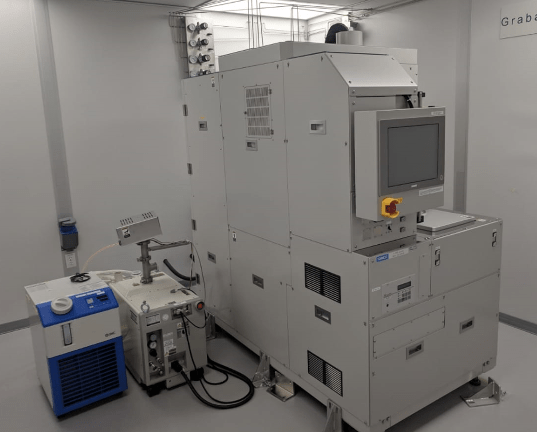

The DRIE system, is characterized by performing dry attacks (based on plasma) on Silicon wafers using the “BOSCH” method named by Robert Bosch.

“Deep Reactive-Ion Etching” DRIE system of the CIDESI Querétaro cleanroom.

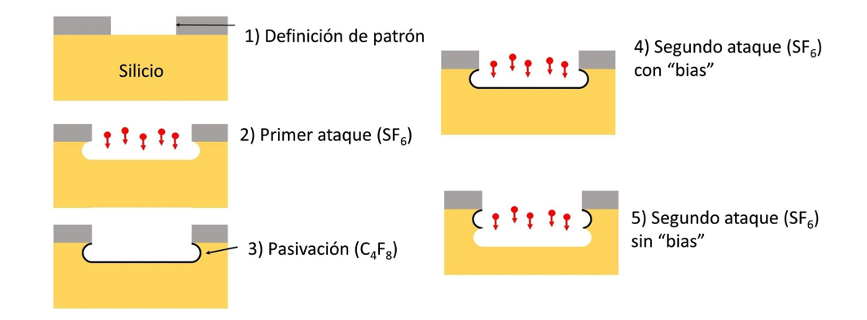

The process is characterized by being a highly anisotropic etching process that is used to create deep penetration perforations (from a micro-fabrication point of view) for the creation of complex structures during MEMS manufacturing, where attacks by wet processes fail to resolve, it is characterized by implementing three fundamental steps (protective layer deposit, protective layer pattern attack and silicon attack) of short duration which represent an attack cycle (approximately 19 seconds) and the amount of material removed will be controlled by the number of cycles. However, the complete process consists of 5 steps illustrated in Fig. 2, which are described below:

General description of the DRIE process.

Pattern definition: In this step, the pattern to be captured on the surface of a silicon wafer is defined through photolithography processes, the advantage is that any two-dimensional geometry can be patterned to subsequently penetrate the silicon bulk, unlike wet attacks totally dependent on the crystallographic orientation of Silicon. It is very important to consider what type of material will be used to define the pattern because it is the one that will allow you to reach certain desired depths depending on the selectivity with respect to Silicon, generally you can use photoresist, SiO2, Si3N4, Cr, among others protective layers.

First attack (SF6): This process is characterized by making the first attack of Silicon and defining the beginning of the cavity, where the protective layer also suffers damage, but at a lower level, for this process a plasma based on SF6 with a small part of O2 without ion acceleration, it is important to mention that the time is relatively very short 1-2 seconds because the longer attack time, the walls will be damaged.

Passivation (C4F8): In this process, a protective layer of Teflon is deposited using a C4F8-based plasma, covering surfaces and cavities in a “conformal” manner, in order to protect the walls.

Second attack (SF6) with “bias”: This step is used to remove the protective Teflon previously deposited using a plasma based on SF6 with O2 but with acceleration towards the surface, achieving the removal of the protective layer located on the surface of the silicon and on the base of the cavity leaving only teflon protection on the walls.

Second attack (SF6) without “bias”: This step is immediate to the previous step with the difference of not using ion acceleration and higher pressure inside the chamber to generate the next attack of the cavity in the silicon, for a short time, to avoid damaging the walls.

Attack cycle: This process consists of repeating steps 3, 4 and 5 as many times as necessary, a complete cycle can take around 19 seconds depending on the recipe to be used, which in turn depends on the structures to be defined, the speed The attack rate will also depend on the exposed area of the cavity, so it is important to always characterize the attack speed for each particular sample with the possibility of making small adjustments to the recipes.

What kind of devices can we manufacture with the DRIE system?

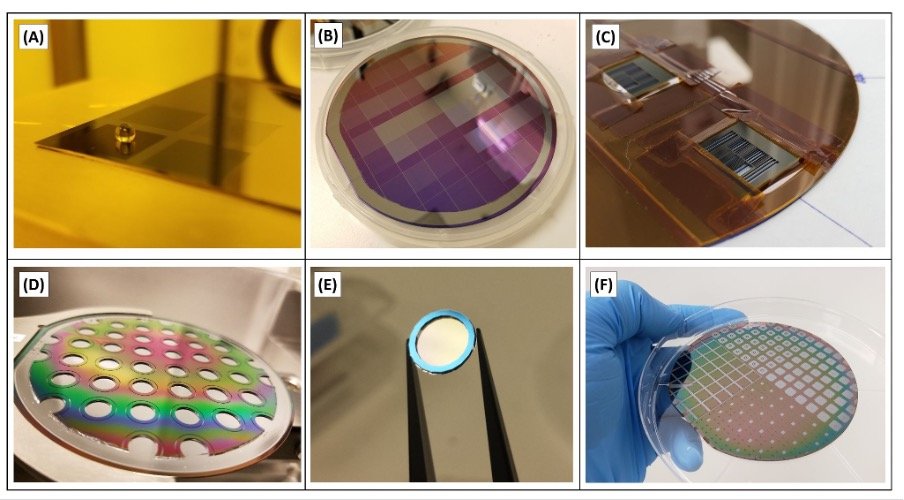

The area of application is very extensive for this type of system, ranging from electronic devices such as capacitors, to systems with micro-mechanisms and even micro cameras for flow or gas sensors. In Figure 3 you can see different types of applications that the microtechnologies work team at CIDESI has carried out using the DRIE system.