In a common device or integrated circuit manufacturing process, generating a guide template that determines the geometries and dimensions of the microdevice is an important step. In medium and large-scale productions of devices or integrated circuits, photomasks are used, which through photolithographic processes will generate the patterns that the films of different materials will be exposed to, which will allow us to materialize our micrometric device.

The pattern generator of the clean room of the Division of Microtechnologies at CIDESI Querétaro, is an instrument that by exposing a laser with a wavelength of 375 nm, is responsible for generating or recording 2D geometric patterns to complex 3D structures depending on the resist used, with accuracy of up to 4 µm in exposure areas of up to 63 x 70 cm². In addition to providing tools such as position measurements and alignments to perform multi-layer overlapping exposures with high precision.

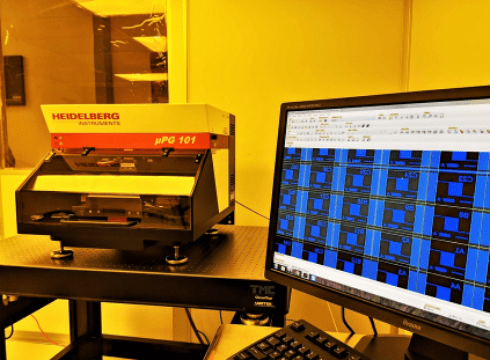

Laser writer HEIDELBERG uPG 101

The equipment is used mainly for the generation of photomasks for its later use in UV exposure equipment and alignment. However, the versatility of the equipment allows us to generate patterns directly on substrates, commonly glass or silicon.

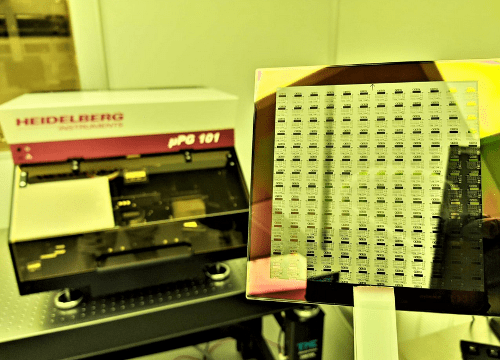

Micrometric device photomask processed

For the fabrication of photomasks, the starting point is a glass substrate with a deposited stack of chromium followed by a photosensitive resist. The mask writer, by exposing its laser in XY coordinates, sensitizes the resist, which makes it soluble or insoluble to the developer of its type, depending on whether it is resist of the positive or negative type respectively. After the exposure (pattern engraving), the development process is carried out where the soluble areas of the mask are eliminated generating exposed areas of chromium, these areas will later be chemically attacked, generating the translucent windows through which the light will pass in the photolithographic processes.

Design and manufacture of photomasks.